- Logistic & Storage

- Storage solution

Ultraflex Storage

ESSEGI UltraFlex storage family

The ESSEGI ISM Ultraflex family handles the material with carriers and is 100% reliable.

- Capacity up to 3600 8mm reels

- Smallest footprint

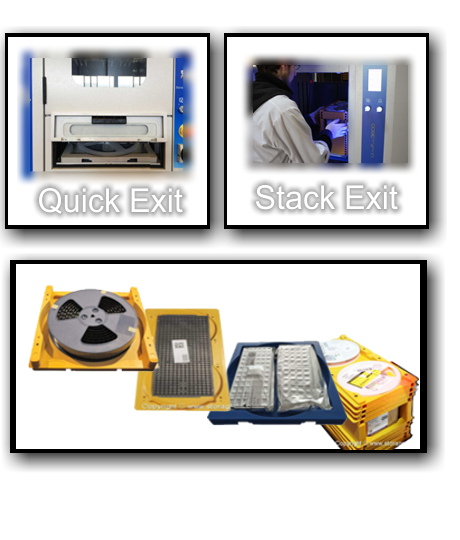

- Stack or single un- & loading

- 100% reliable system

- No direct component contact

- Storing Reels,

trays,

component strips,

dry bag components

ISM 1800 & ISM 3600

Exclusive advantage:

- No need for positions set up in advance.

- No need to reconfigure the stock setup.

With ISM Ultraflex you don't need to pre-set the height of the inner positions to stock the components.

&nb

| ISM1800 | ISM 3600 | |

|---|---|---|

| capacity max. | 1800 reels | 3600 reels |

| technical details | |

|---|---|

| ISM 1800 | |

| Reel with: | 8 - 88mm |

| No special box for trays needed | |

| Patented Fast Exit: | Simultan loading and unloading process |

| Fast Exit: | Ultra Fast loading and unloading of single reels while running Stock process Einzelrollen parallel zum aktuelle laufenden Lagerungsprozess |

Modular Ultraflex storage solution

ESSEGI Modulare UltraFlex storage solution

The Ultraflex Systems are able to install as Back to Back or Side by Side combination.

It offers an expandable storage capacity solution.

- Direct internal component handling

- Side by Side setup for parallel

Load / Unload function

- Installation for loading from Stock area

unloading on SMD side

- Automatic un-/ loading with AIV

- Example:

ISM3600 + ISM3900 + ISM3600 =

capacity of up to 11.100 reels

Workflow with UltraFlex

- Workflow by incoming staion integration

- For new material registration and booking

- Datalink of ISM Ultraflex systems with

- ISM dry chamber

- External shelfs (dynamic storage managment)

- Trolleys

- Link to SMD pick & place systems

- Link with ERP system

Logistic automation

The Essegi UltraFlex Systems are able to adapt with automatic loading docks.

This offers the production team, to place their material on trolleys.

Essegi also offers an automation solution, where “autonomy vehicles” are parking in docking stations for automatic loading or unloading process.

Drying cabinet

ESSEGI ISM Drying cabinet product family can store coils, microprocessors trays, SMT and PTH sticks, frames, stencil plates and many other materials.

Fully integrated in the Essegi Stock management system, it is an optimal add on for the automatic ISM Storage systems as well to third party shuttle storage machines.

- Dynamic storage, no waste

- Zero pickup errors

- Wide selection of positions

- Interaktiv LED marked stock locations

- 2 Systems, many setup available

The ISM500 and the ISM400 systems are store coils, microprocessors trays, SMT and PTH sticks, frames, stencil plates and many other materials. Up to 640 different positions for 7/13/15 inch reels.

Three LED light signals indicate

A PDA reader indicates the component code, to avoid errors in the picking phase.

Dynamic storage,

Humidity control control and the moisture level is constantly below 5%.

Accurate calculation of the "Floor Life"