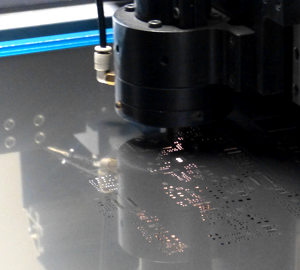

VectorGuard stencil production

For all manufacturing process are several of single steps necessary, where a very good process knowledge is needed. Our team aware of the responsibility and investigate confidential your data files and optimize, if required, the design with long time experience.

Each production step is based on strong internal quality rules and will finalized with a high end check for "all" VectorGuard® stencils.

The outcome is a high end tool for optimized printing process results and reduce running cost.

Our team

Our stencil division cooperate with ASM stencil division, the world largest stencil manufacture. This offers our customers the latest technology for all the actual requirements.

This includes not only, the design rules, as well the tension frame technique, manufacturing method and stencil materials. The product range includes stainless, steel-, FineGrane-, nickel and electroformed nickel stencil.

Additional, the ATT stencil team optimized your product with High End finishing for better separation process with Nano- and Ultra Nano coating.

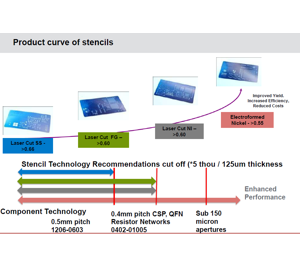

Best stencil

The bandwidth of processed components includes simple SMD components and apertures as well fine pitch, µBGA LLP and include also smallest size up to 01005. The demands on needed stencils is very different.

For the standard technology the behavior of the stainless steel stencil an acceptable print and separation. Apertures of 0,4 pitch or for components smaller then 0402, the Fine Grane stencil reduce the running cost by better separation, reduction of underside cleaning cycle and better quality.

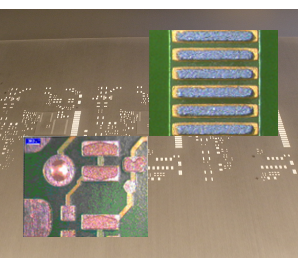

Optimal design

Not every design is perfectly usable to get a perfect and problem solving printing process. Bad design causes downtime, quick smearing on the stencil and therefore short cleaning interval, bad separation and printing result.

The ATT screen team optimize, on request, the stencil design for perfect and cost optimized printing process.