- Soldering units & Rework

- Rework

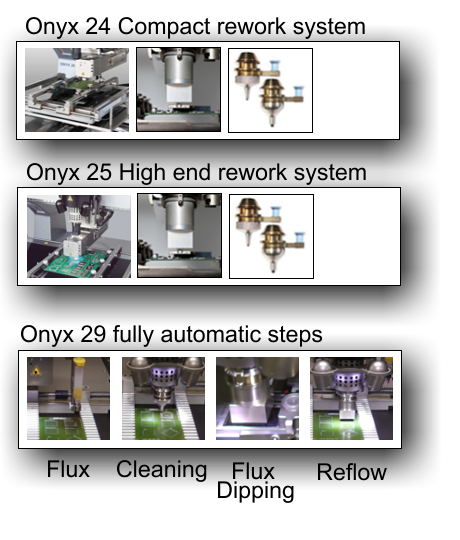

Premium Hotair Rework Onyx Family

ZEVAC ONYX Family

The machine precision, automatic processes and easy operation have been the basics for the development of this new platform.

VISION SYSTEM

advanced MFOV Vision System allows to see components as large as 75 x 75mm.

FORCE MEASUREMENT SYSTEM

Beneath other parameters, the force measuring system is used for placement to protect sensitive components and allows process automation.

SITE SOLDER REMOVAL SYSTEME

especially for the rework of BGA's, the fully automatic Site Solder Removal System is an important feature

System features

All systems with:

- automatic process control

- non contact solder removing process

- controlled force Z-axis measurement

- motorised 4 axis

ONYX 24

| max. PCB size | W 300mm x D open |

|---|---|

| max. comp. size | 75 x 75mm |

| axis control | manuell |

ONYX 25

| max. PCB size | W 560 mm x D open |

|---|---|

| max. comp. size | 75 x 75mm |

| axis control | manuell |

ONYX 29 fully automatic rework system

| max. PCB size | W 500 mm x D 500 |

|---|---|

| max. comp. size | 75 x 75mm |

| axis control | automatic |

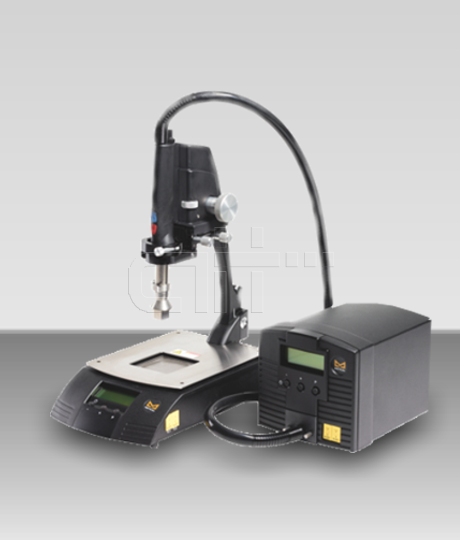

THT miniwave rework SSM4A

ZEVAC Selective table top system

The SSM rework series, is a professionell solution for THT rework process.

It offers options like:

- machine board holder support

- cover, blow out system

- connection to an external fume exhaust systems

Reproducible results as parameters like:

- solder temperature

- cycle time

- wave height

- ramp up and down

Footswitch control available on demand.

SSM4A

- Manual control THT rework mini wave system.

- The system provide a strong blowout function

to open the through holes in the PCB after

removing the component.

SSM9

- Fully programmable and programm controled

THT rework mini wave system.

- Even the solder height ramp up and ramp down

phase can be programed on demand.

- The system provide a strong blowout function

to open the through holes in the PCB after

removing the component.

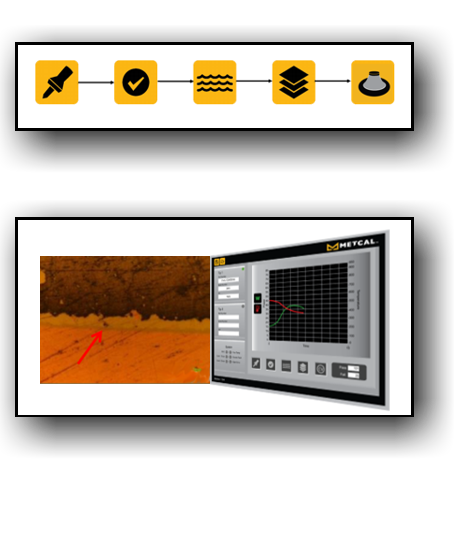

CV-Connection validation Rework systems

Metcal CV 500 & 5200

- KEEP Your intermetallic zone under control.

- 100% soldering control

- Record the soldering events

- Verify the used tips

- Setup the process parameters

- Control the process parameters

- Trace the hand soldering events

Metcal offers with the CV Product Line the solution, to validate continuously the solder joint quality and the IMC. The system will give a feedback after reaching the optimal soldering time. It can also be used for validate the optimised tip and soldering temperature. Combining the Tipshape; temperature and the gradient, it will calculate the correct soldering time.

Process control steps:

- Recognise the inserted tip

- Recognise the start point

- Detect the melting point

- Calculate the correct IMC

- Optical and/ or acustic feedback

- confirm success or failed event

- Solder event logging

ECO Hotair Rework MRS-1100

Metcal MRS-1100A

The Metcal hotair rework stations are powerful tools for all electronic- non contact soldering needs.

- Simple programmable

- Stand for hand piece

- Self containing air pump

- Lightweight hand piece

- Integrated hand piece holder

- Integrated vacuum pump

- Long life heater

- Hot-air follow-up time

Technical details:

- 600 W Top heater

- 1200W bottom heater

- 50 programmable temperature profiles

- 50 programmable Airflow profiles

- Cloosed Loop profile control with external sensors

- Remote PCT1000 control

- Self containing Air pump